Drilling fluid are used in the drilling process to keep the drill bit cool & carry the down hole drilling cuttings up to the surface of the well. To maintain the specified viscosity and density of the drilling fluid, some drilling fluid agents such as barite, bentonite, etc. must be added into the fluid in the drilling process. Previously centrifuge are used to add these fluid agents into the drilling fluid, but now jet mud mixer or some called mud hopper are used specially to complete the adding processing in the solids control system.

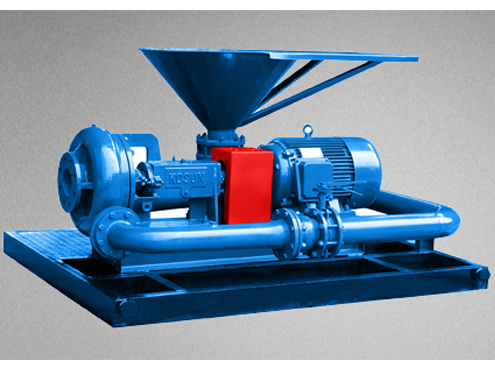

Jet Mud Mixer

Installation requirements of drilling jet mud mixer:

1. General requirements mixing hopper capacity shall not be less than 150m3/h. For the larger mud tank and great pump motor power, we can also use the mixing hopper with 300m3/h capacity.

In order to ensure the required well pressure, suggest that each drilling crew should equipped with a spare set of mixing hoppers, in most cases spare hoppers used overlap mode.

2. The return pressure of outlet pipe needed moderate, overlarge return pressure will reduce the treating capacity of mixed hopper.

3. The gap between nozzle and venturi tube must be suitable, when reach optimum efficiency, the gap is 32~90mm, usually don’t more than 90 mm, otherwise the feed speed of barite will be significantly reduced.

4. Another important consideration of install equipment is the drilling fluid required lifted height. If discharge needed to enter into different deck tank or a taunt tank and hopper, mix rate will be decreased. When the height from 1.83m to 3.66m, barite adding rate will be reduced to 17%. If the increased demand is very high, the pump capacity is insufficient, mixed ability will be greatly reduced.