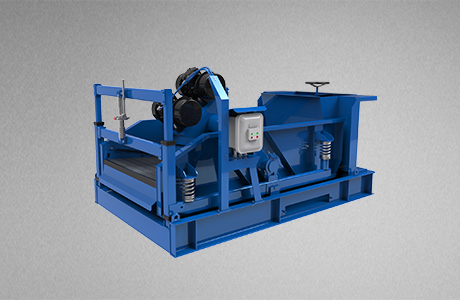

Shale shaker consists of vibration motor, compound rubber spring, stainless steel shaker screen mesh framework, screen box and start switch.

The product through the vibration motor which drives the eccentric block moves high speed. The strong centrifugal force acts on the elastic vibrator make the bottom of the screen frame secured to the frame of the screen plate vibrating at high frequency, the larger screen of the drilling cuttings dropped.

Shale shaker plays an important role in the performance of the solids control system. Which including oil & Gas drilling system,HDD &Underground System, CBM & Geothermal well system and Mining & Environment system.

Firstly, check the Logging can import leak or not, according to the request fasten the inlet connection. Each shift with water hose to sediment generation equipment operation process from the device wall and sieve bed clean. These deposits will increase the damping block load and reduce the ability of vibrating screen separation of solid particles. Inspecting the screen wedge fast fixed and working state when each shift happens. Pay attention to the hole or other defects otherwise the rigid granules will flow away. If the screen is damaged, should be replaced timely.

Secondly, during the using process, if there is drilling fluid paste net phenomenon, the screen should be cleaned in time.

Thirdly, washing sieve immediately with water in time and then use a clean hair brush to brush the drilling fluid on the screen and the sand embedded in the mesh when the shale shaker stop working,. During the process of tripping shale shaker has stopped running without circulation, for a long time, the drilling fluid viscosity is often more than 100 mu, the mud into the screen slots should be pass valve open, and close the vibrating screen the import side board at the same time, to prevent the high viscosity of the drilling fluid flowing to the screen mesh screen and paste it badly. If board closed laxly, drilling fluid flow into the screen, use the water to wash immediately.

Fourthly, it is forbidden to step and make pressure on the shaker screen, prohibits any remaining items on the screen in the process of transportation when lifting. We must use 4 M20 bolts x 110 to fix the shale shaker with the base, prevent the damage of screen box caused by severe vibration.